If cows were given a choice

Then they would choose an optimal quality of roughage. A healthy cow produces more high-quality milk!

The quality of the roughage depends on the covering method. It is all about good preservation, which is why a good covering system is essential in addition to the slot silo elements. This silo cover system ensures a fast, efficient and virtually airtight and watertight seal of the roughage.

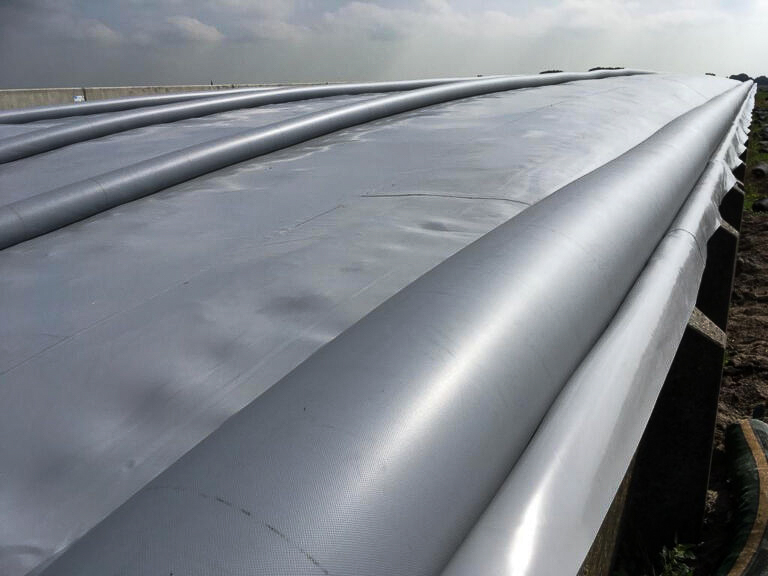

The silo cover system consists of a specially designed slot silo cover and a slot silo cover machine. Water hoses (105 kg / m1) are fitted over the entire length of the slot silo cover, these hoses are filled with (salt) water. As a result, the cover is stretched tightly, almost vacuum over your roughage. The loss of roughage is thus reduced to a minimum because almost no air and (rain) water can get between the cover and your roughage.

Twelve years of experience have shown that the elastic heavy cover ensures optimal conservation of your roughage. The cover has a weight of 1.7 kg./m2, is resistant to crows and provides an effective and fast airtight seal with optimal water drainage.

This preserves the grass in a much shorter period of time, partly because more sugars remain behind in the roughage and it becomes less susceptible to scalding.

With this system, the conditions of the roughage remain optimal and it simplifies the way of silage and excavation, keeping the cow healthy and providing stable milk quality.

Convenience serves people

By using the machine in combination with the hydraulics of your telescopic handler or tractor with front loader, the cover can be rolled quickly and easily over the pit. This is all you need to do!

Less labour intensive – hydraulically mobile

The cover system is also hydraulically movable over the slot silo walls. This works quickly and efficiently.

The design of the slot silo cover is designed to improve the quality of the roughage, save labour and the make it easy to use for the farmer. The expected service life of the silo cover is 10 to 15 years. The oldest covers are in the 12th season.

The advantages of the silo cover system

By covering the roughage well, you get a considerably better quality of feed for the cows and it works more efficiently.

Kornet offers a silo cover system with an elastic cover with a weight of 1.7 kg./m that is also resistant to crows. With an effective airtight seal and optimum drainage of rainwater and press juices, this cover improves the quality of the roughage.

More information about the Kornet silo cover system? Would you like more information about our feeding systems?

roll for cover

hydraulic system

Because the tubular water pouches (± 105 kg. per linear metre) are pressed as a wedge between the roughage and the silo wall, a perfect seal is obtained. The heavy water tubes pull the elastic cover down, so that the covers sit tight as an elastic band over the roughage. The cover is crow-proof and has the same properties as shrinkwrap.

The elastic cover can be easily pulled off the roughage product in one go with the hydraulically driven machine. This is made possible because there are reinforced longitudinal pull ribbons in the cover. As a result, the cover cannot be broken or pulled porously.

When the cover is removed, with interim silages, the sweet scent of the product meets you.

Even when the farmer opens the grass silage for the next layer of product, this is easy and fully automatic. The system runs perfectly straight on the roll through a fixed reference on the slot silo wall.

Cover roughage with the silage cover system

Covering your roughage is easy and quick! When you are ready and the silage is stuck in the silo, it does not take much time to cover the silage. You do not need any help from others to cover it, only a tractor with a front loader, shovel or telescopic handler is required. Or possibly it can be moved completely hydraulically!

Connect the covering machine and operate the machine via the hydraulics. From the rear, unroll the cover over the hump.

As soon as the cover is unrolled, connect the water hoses to the KCS filling system and the overflow system. The water hoses of the cover can now be filled. Filling the water hoses is easy by using the included Kornet Cover Solutions filling system. With a silo of 40 by 10 wide, the water hoses are filled in about 40 minutes. You do not have to constantly keep up with this, it is secured with an overflow system. Only check regularly if everything goes well. When they are filled, disconnect the system.

Thanks to our extensive experience and knowledge, we can optimise the portal system for you so that it leads to higher returns.

Feeding with the slot silo cover system

The excavation of the silage is easy and fast. You do not have to remove straps and gravel hoses first and expose the hump. Simply place the covering machine on the selected slot silo, at the start of feeding. The next time you start feeding, all you have to do is connect the covering machine to your tractor with front loader, shovel or telescopic handler. The machine rolls up the desired number of metres of the cover, you decide how much roughage will be released. Then you disconnect the machine. This takes only a few minutes. The covering machine remains on the slot silo as long as you are feeding from the silo.

The cover system is particularly easy with severe weather conditions such as snow or wind. With the cover system you can easily roll up the cover despite the snow, as was also the case in the winter of 2009/2010. This way you are always sure that you can feed.

Because the machine with the roller and the cover remain above the roughage, you work as it were behind a “screen”. As a result, your exposed roughage remains considerably drier, which offers you advantages when feeding by weight.

An overflow system at height ensures in all cases a good and even filling of the hoses. As a result, the water hoses always remain well filled with the correct amount of (salt) water.

Specific information about the KCS cover system

The cover system is supplied complete, including:

- Cover machine

- Elastic heavy cover (1,7 kg./m2)

- Filling system; pump

- Overflow system

- Instruction upon commissioning

The KCS covering machine is available in 3 sizes:

- The KCS – 1000 for slot silos from 6 to 10 metres wide

- The KCS – 1200 for slot silos from 8 tot 12 metres wide

- The KCS – 1500 for slot silos from 11 tot 15 metres wide

The KCS covering machine complies with the European Machine Directive and comes with a 2B certificate.

The KCS cover system is subject to the Dutch MIA & VAMIL regulations and environmental investment schemes. These are tax relief schemes for businesses investing in environmentally friendly farm equipment.

For more information, a non-binding offer or an appointment, please feel free to contact us.

More information?

For more information about the Kornet silage solutions or a check of your roughage, please contact us via:

Mobile: +31 (6)-51414299 or Office telephone number: +31 (0)514 601990